Fiber Laser Cutting Machine

FRC Series, apply the most mature laser cutting technology, high performance, fast response and maintenance free, qualified for ultra-high precision processing requirements.

Tel.: +86-21-6034 3841 (UTC+08:00, 9:00~17:00) / +86 136 0179 0660 (24*7 Hours)

E-mail: info@ambermont.com Fax: +86-21-6766 9623 (UTC+08:00, 9:00~17:00)- Product Introduction

- Technical Parameters

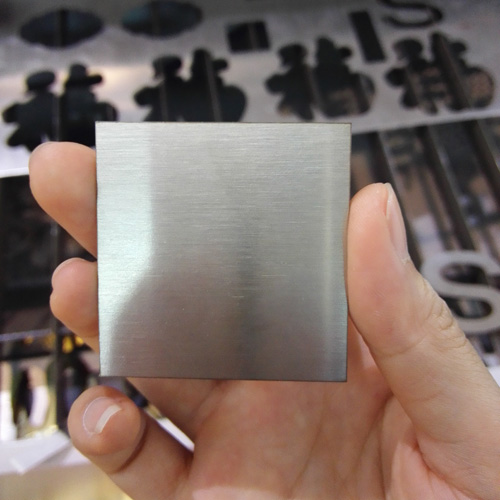

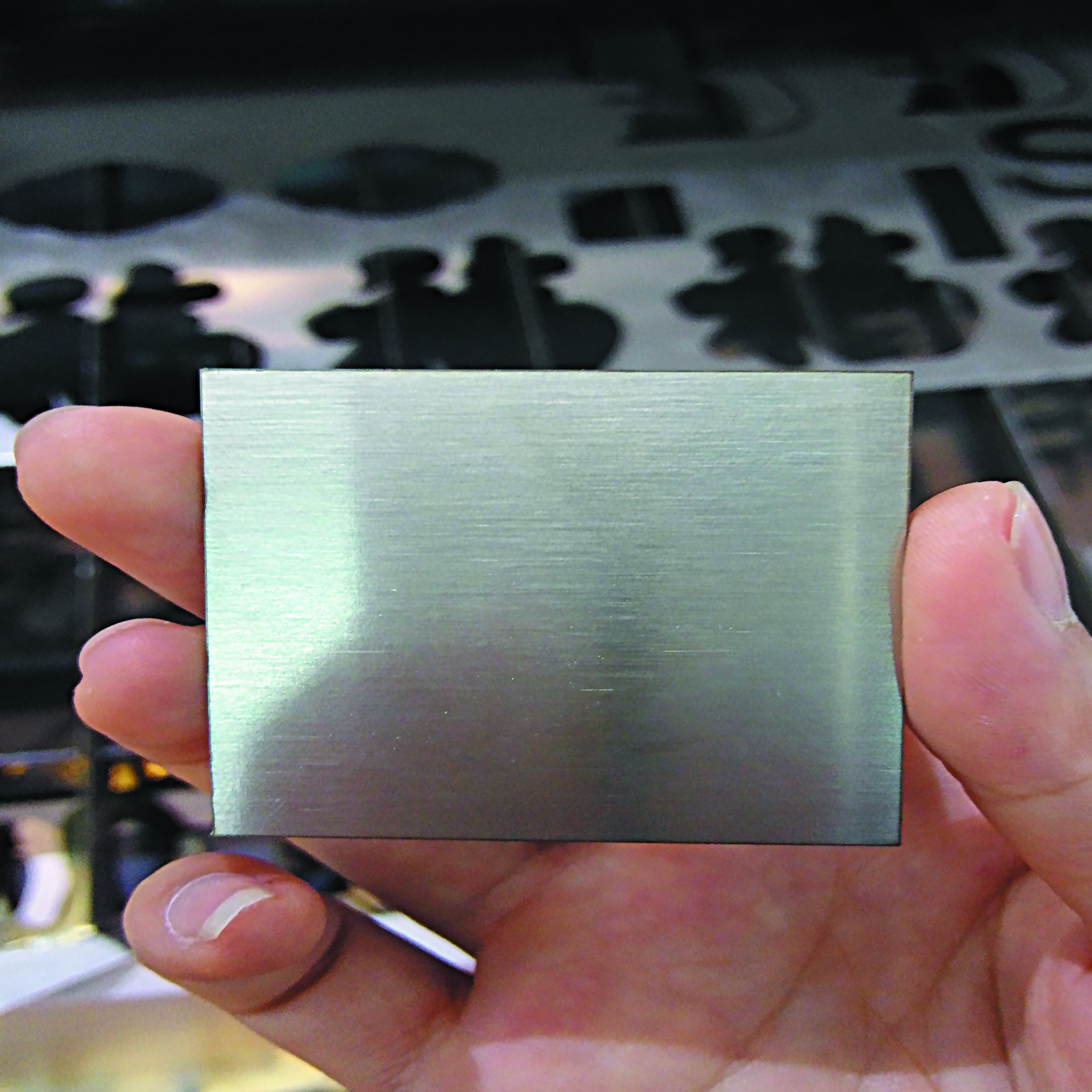

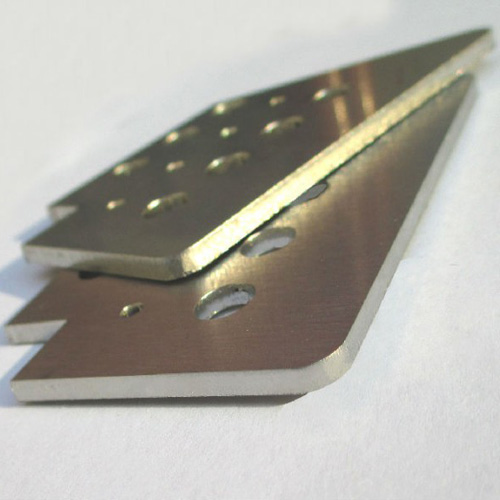

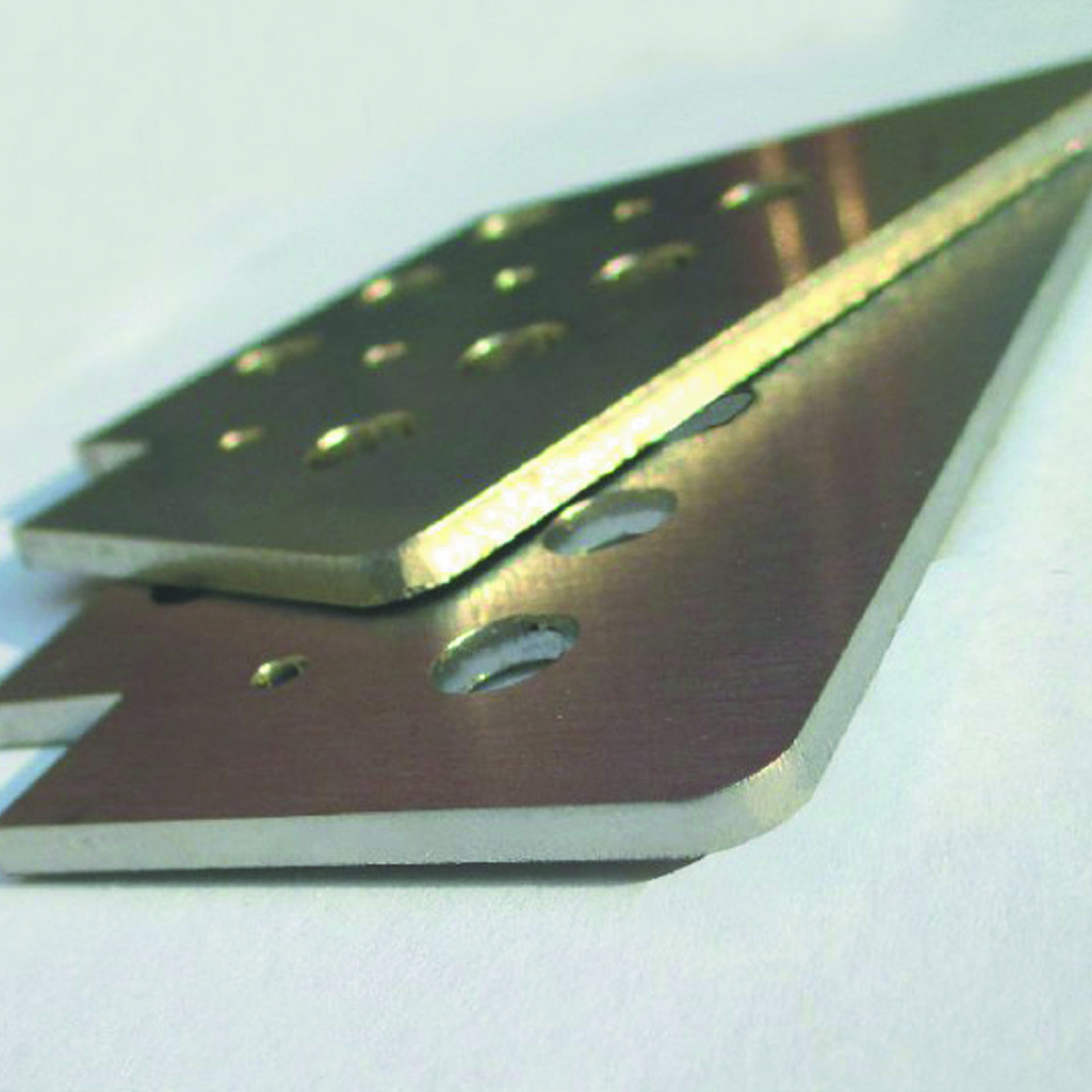

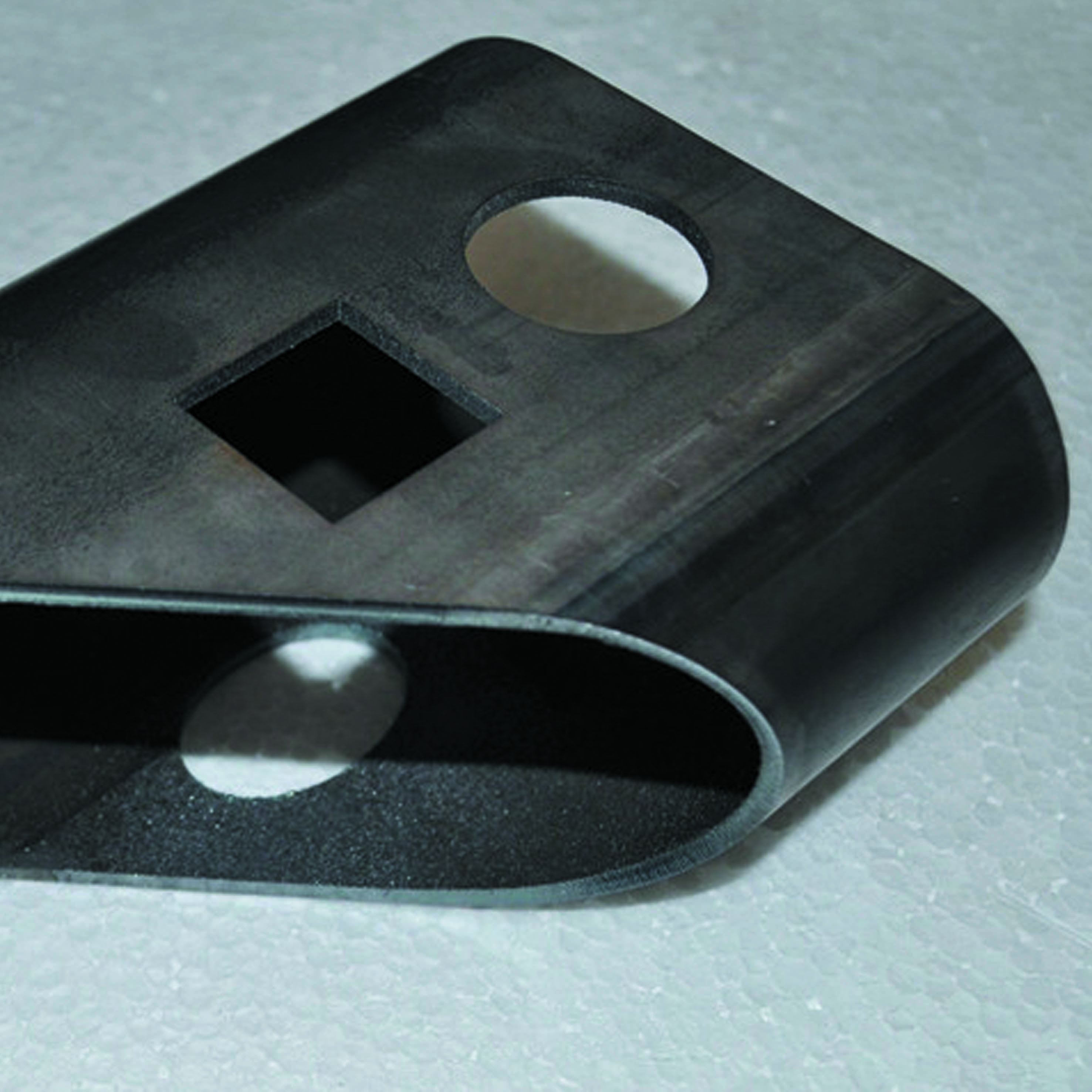

- Samples Display

Product Introduction

Integrating laser technology, machinery manufacturing and CNC technology, etc. Adopts gantry-motion structure, high precision rack & pinion double driving system, AC servo motor and drives, vacuum system (both sides), etc. It offers high flexibility, easy materials handing and high accuracy for faster and more profitable parts.

● Professional laser cutting operation system with multi-language user interface , which greatly facilitates the operation;

● The whole frame, 600℃ heat treatment, 24 hours furnace cooling, 12 meter milling machine processing, ensure 20 years' working without any deformation;

● Apply the most mature laser cutting technology, high performance, fast response and maintenance free, qualified for ultra-high precision processing requirements;

● Adopts gantry-motion structure, linear guide, double transmission, AC servo motor and drives, vacuum system (both sides), etc. Imported high precision rack and pinion, smooth transmission, fast acceleration and high locating accuracy;

● Professional laser cutting operation system with multi-language user interface , which greatly facilitates the operation;

● The whole frame, 600℃ heat treatment, 24 hours furnace cooling, 12 meter milling machine processing, ensure 20 years' working without any deformation;

● Apply the most mature laser cutting technology, high performance, fast response and maintenance free, qualified for ultra-high precision processing requirements;

● Adopts gantry-motion structure, linear guide, double transmission, AC servo motor and drives, vacuum system (both sides), etc. Imported high precision rack and pinion, smooth transmission, fast acceleration and high locating accuracy;

It's specially used for cutting 0.5~6mm carbon steel, 0.5~5mm stainless steel, galvanized steel, electrolytic zinc-coated steel, silicon steel, 0.5~3mm aluminium alloy, 0.5~2mm brass and other kinds of thin metal sheets.

Technical Parameters

| Models No. | FRC 3015 |

|---|---|

| Laser Rated Power | 800W/1000W |

| Wavelength | 1064nm |

| Processing Area | 1500*3000mm |

| X Axis Stoke | 1505mm |

| Y Axis Stoke | 3015mm |

| Z Axis Stoke | 200mm |

| X/Y Axis Max. Linked Speed | 80m/min |

| Max. Acceleration | 1.0G |

| X/Y Axis Positioning Accuracy | ±0.05mm |

| X/Y Axis Repeat Positioning Accuracy | ±0.03mm |

| Max. Workbench Load | 500KGS |

| Transmission | High-precision rack & pinion + double driving system |

| Rated Power | <15kW |

| Power Supply | 380V/50Hz |

| Total Weight | 5500KGS |

| Dimension (l*w*h) | 4890*2470*1730mm |

Samples Display