Fiber Laser Cutting Machine

FRT Series, it's not only implements automatic production, but also breaks through the limitation of plates cutting. Achieved multi-dimensional cutting, it is the optimal choice for metal tube laser c...

Tel.: +86-21-6034 3841 (UTC+08:00, 9:00~17:00) / +86 136 0179 0660 (24*7 Hours)

E-mail: info@ambermont.com Fax: +86-21-6766 9623 (UTC+08:00, 9:00~17:00)- Product Introduction

- Technical Parameters

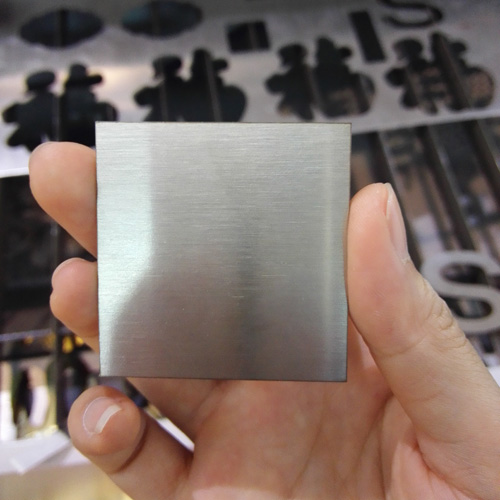

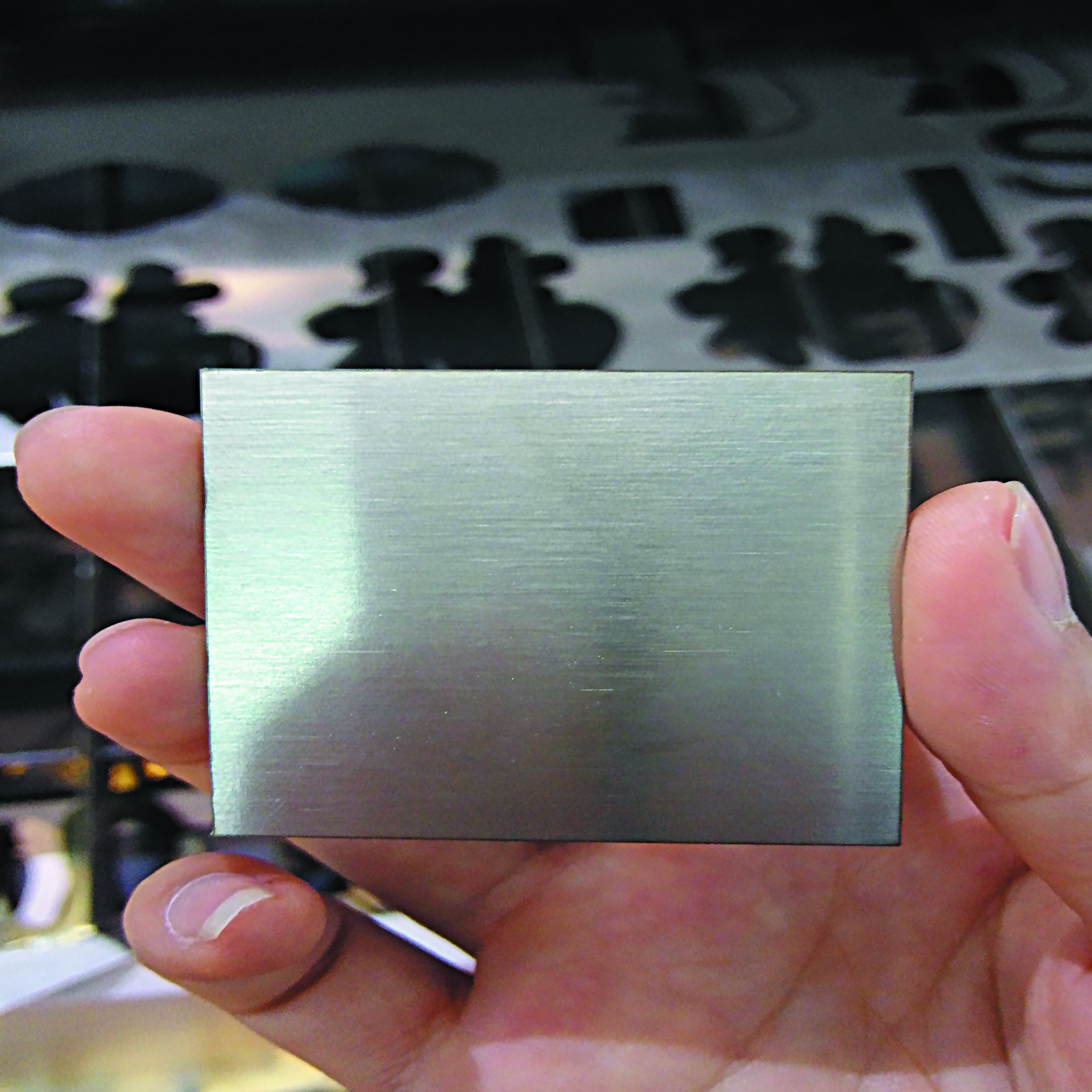

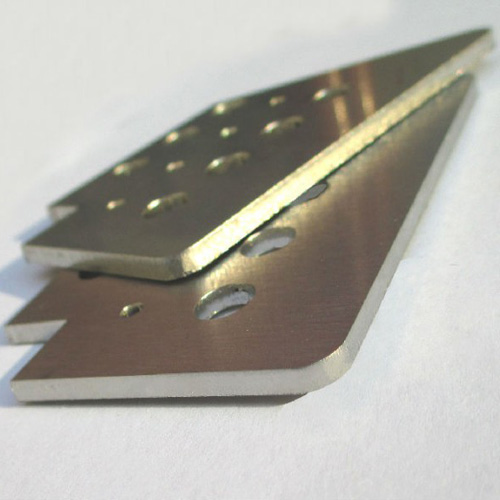

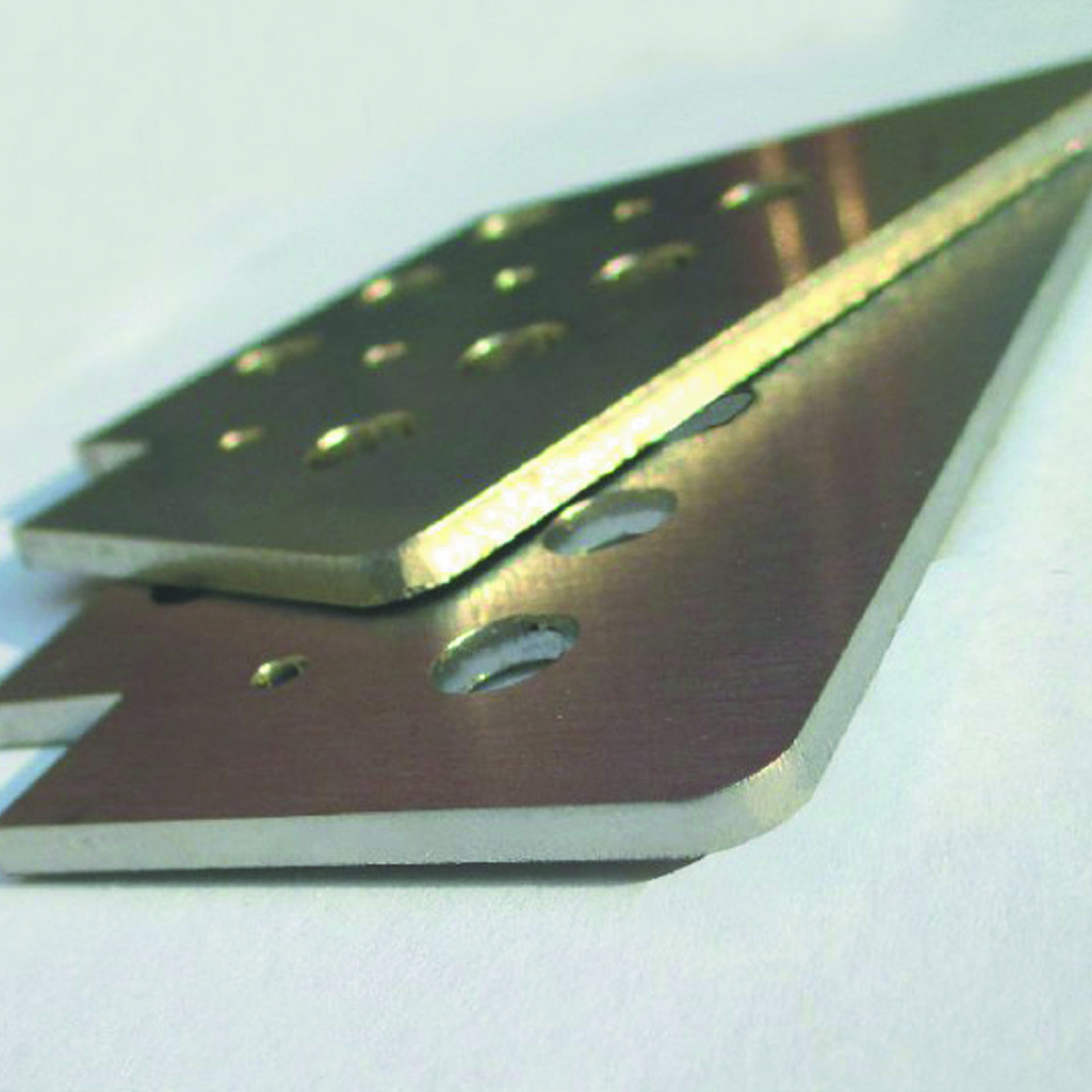

- Samples Display

Product Introduction

AmberMont devote ourselves to researching & developing FT series plates-pipes fiber laser cutting machine, integrating the fast-speed full automatic laser cutting technology, it’s not only used to cut all kinds of metal sheets, but also cut circle tubes, rectangular tubes and other irregular-shaped tubes.

● Cut metal sheet and metal pipe in one laser cutting machine, cost-saving and high performance-price ratio;

● Professional laser cutting operation system with multi-language user interface , which greatly facilitates the operation;

● The whole frame, 600℃ heat treatment, 24 hours furnace cooling, 12 meter milling machine processing, ensure 20 years' working without any deformation;

● Apply the most mature laser cutting technology, high performance, fast response and maintenance free, qualified for ultra-high precision processing requirements;

● Adopts gantry-motion structure, linear guide, double driving transmission, AC servo motor and drives, vacuum system (both sides), etc. Imported high precision rack and pinion, smooth transmission, fast acceleration and high locating accuracy;

● Cut metal sheet and metal pipe in one laser cutting machine, cost-saving and high performance-price ratio;

● Professional laser cutting operation system with multi-language user interface , which greatly facilitates the operation;

● The whole frame, 600℃ heat treatment, 24 hours furnace cooling, 12 meter milling machine processing, ensure 20 years' working without any deformation;

● Apply the most mature laser cutting technology, high performance, fast response and maintenance free, qualified for ultra-high precision processing requirements;

● Adopts gantry-motion structure, linear guide, double driving transmission, AC servo motor and drives, vacuum system (both sides), etc. Imported high precision rack and pinion, smooth transmission, fast acceleration and high locating accuracy;

It's specially used for cutting 0.5~6mm carbon steel, 0.5~5mm stainless steel, galvanized steel, electrolytic zinc-coated steel, silicon steel, 0.5~3mm aluminium alloy, 0.5~2mm brass and other kinds of thin metal sheets.

Technical Parameters

| Models No. | FRT 3015 |

|---|---|

| Laser Rated Power | 500W/700W |

| Wavelength | 1064nm |

| Processing Area | 1500*3000mm |

| X Axis Stoke | 2180mm |

| Y Axis Stoke | 3015mm |

| Z Axis Stoke | 200mm |

| X/Y Axis Max. Linked Speed | 33m/min |

| Max. Acceleration | 0.3G |

| X/Y Axis Positioning Accuracy | ±0.05mm |

| X/Y Axis Repeat Positioning Accuracy | ±0.03mm |

| Max. Workbench Load | 500KGS |

| Transmission | High-precision rack & pinion + double driving system |

| Rated Power | <15kW |

| Power Supply | 380V/50Hz |

| Total Weight | 4300KG |

| Dimension (l*w*h) | 4915*3035*1580mm |

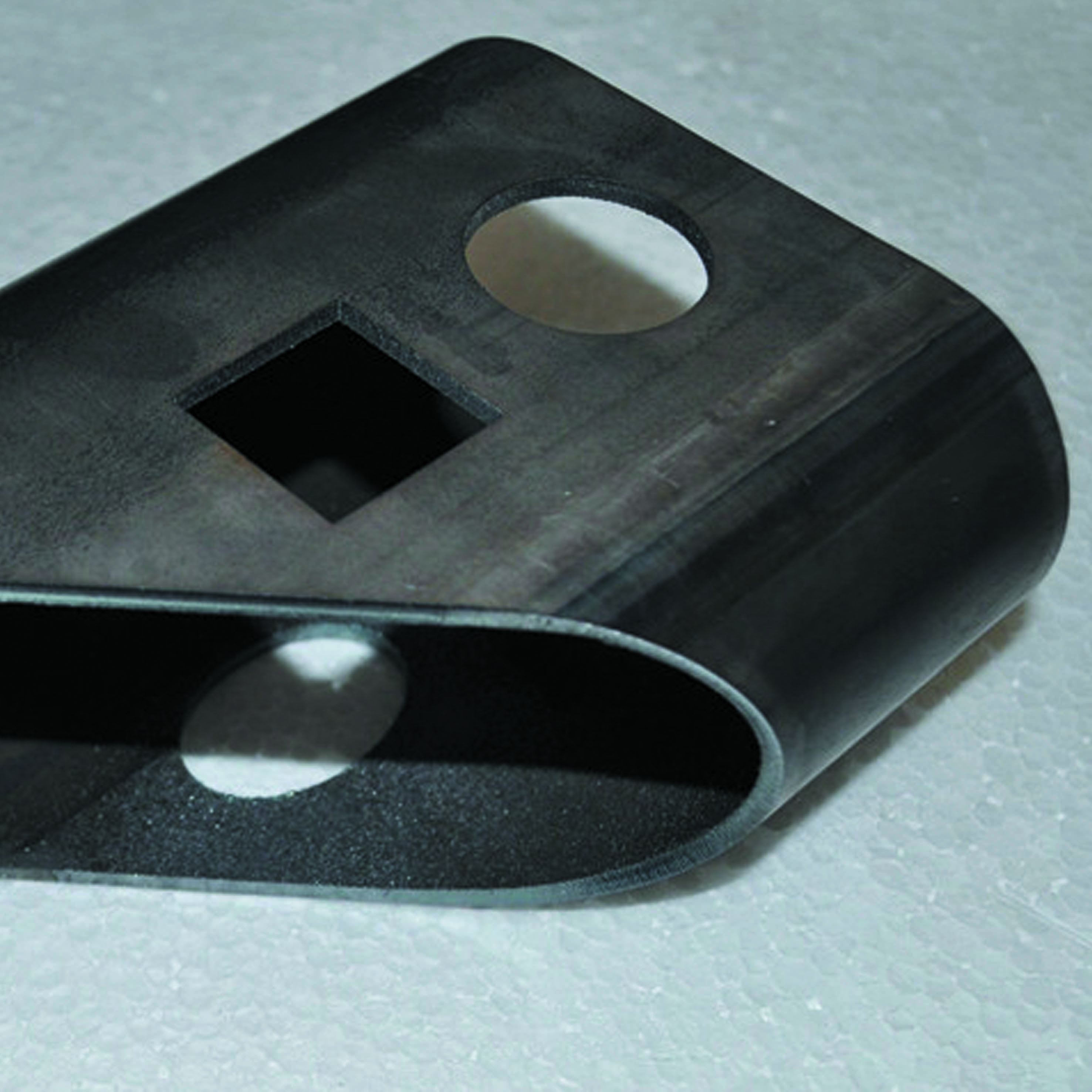

Samples Display